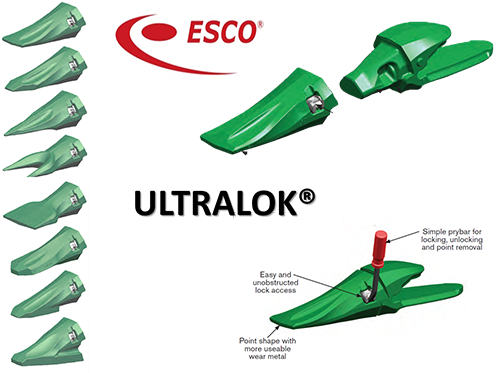

ESCO Ultralok® Teeth

ESCO Ultralok® Teeth

-The Ultralok® is ESCO® Corporation’s innovative hammerless tooth system for loaders and excavators.

-Each Ultralok® tooth has an integrated locking device which makes it a truly hammerless system consisting of two pieces versus the traditional three piece tooth systems.

-Fastening occurs via a simple prybar.

-Safety is increased and field replacement is simplified!

-Tooth Hardness (BHN): 534 throughout entire tooth.

-Sizes:

U20, U25, U30, U35, U40, U45, U55, U60

ESCO Super-V® Teeth

ESCO Super-V® Teeth

-The Super-V® is ESCO® Corporation’s steadfast twist-on tooth system for loaders and excavators.

-Fastening occurs via a quarter turn of the tooth followed by a vertical drive pin, which can be reused up to 6 changes.

-Tooth Hardness (BHN): 534 throughout entire tooth!

-Sizes:

V17/18, V19, V23, V29, V33, V39, V43, V51, V59

ESCO MaxDRP® Teeth

ESCO MaxDRP® Teeth

-The MaxDRP® is ESCO Corporation’s direct replacement line of Caterpillar J-Series® side-pin tooth system for loaders and excavators.

-Fastening occurs via a horizontal drive pin and locking retainer.

-Tooth Hardness (BHN): 534 throughout entire tooth!

-Sizes:

200, 225, 250, 300, 350, 400, 450, 550, 600

ESCO Conical® Teeth

ESCO Conical® Teeth

-The Conical® is ESCO® Corporation’s time-honored vertical pin tooth system for loaders and excavators.

-Fastening occurs via a vertical ratchet lock and pin.

-Tooth Hardness (BHN): 534 throughout entire tooth!

-Sizes:

18, 25, 30, 35, 40, 45, 50, 55

ESCO Helilok® Teeth

ESCO Helilok® Teeth

-The Helilok® is ESCO® Corporation’s time-honored twist-on tooth system for loaders and excavators.

-Fastening occurs via a vertical horseshoe lock.

-Tooth Hardness (BHN): 534 throughout entire tooth!

-Sizes:

17, 19, 21, 27, 37, 47, 57

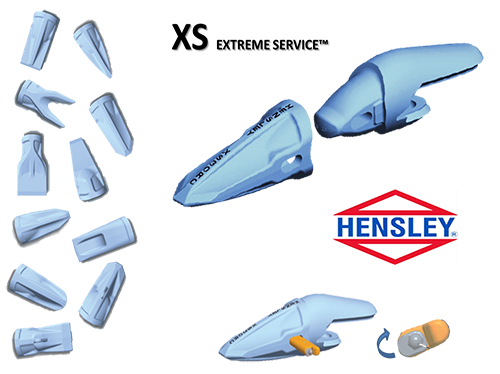

Hensley XS™ Teeth

Hensley XS™ Teeth

-The XS™ (Extreme Service) is Hensley® Industries’ patented hammerless tooth system for loaders and excavators.

-The XS™ system’s streamlined tooth and unique nose design promotes self-sharpening, strength and durability. Safety is increased and field replacement is simplified!

-Fastening occurs via the insertion of a one-piece, hammerless pin and the use of a socket wrench to lock.

-Tooth Hardness (BHN): 477-532 throughout entire tooth!

-Sizes:

XS5, XS10, XS15, XS20, XS25, XS30, XS40, XS50, XS70

Hensley Parabolic® Teeth

Hensley Parabolic® Teeth

-The Parabolic® is Hensley® Industries’ proven vertical pin tooth system for loaders and excavators.

-The tapered surface on the adapter nose allows teeth to fit tighter with each ground engagement.

-Fastening occurs via vertically mounted roll pins or flex pins.

-Tooth Hardness (BHN): 477-532 throughout entire tooth.

-Sizes:

X156, X160, X162, X220, X225, X290, X310, X330, X370, X400, X410, X450, X475, X500, X550

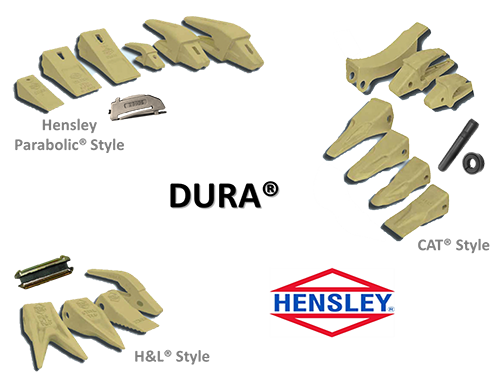

Hensley Dura® Teeth

Hensley Dura® Teeth

-Hensley Industries offers the Dura® line as a quality, low-cost alternative of direct replacement parts for Cat®, H&L® and Parabolic® style tooth systems.

-Hensley proudly stands behind the strength and quality of their Dura® brand with the same dependable warranty protection as the genuine "Blue" products.

H&L Uniforge® Teeth

H&L Uniforge® Teeth

-The H&L Tooth Company’s forged digging teeth are “MADE IN THE USA” and are designed for loaders and excavators.

-During the 1970’s, H&L’s forged 23 Series tooth was awarded the best OEM backhoe tooth in the world. Today, there are many imitations; but if it doesn’t say H&L, it’s not the ORIGINAL!

-Fastening occurs via a horizontal flex pin.

-Tooth Hardness (BHN): 444-514

-Tooth models are also available in a “Value-Cast” option.

-Sizes:

23, 24, 25, 27, 31, 32, 33

ESCO MaxDRP® Ripper Teeth

ESCO MaxDRP® Ripper Teeth

-The MaxDRP® is ESCO® Corporation’s direct replacement product for Caterpillar® side pin ripper tooth system.

-Fastening occurs via a horizontal drive pin and locking retainer.

-Tooth Hardness (BHN): 534 throughout entire tooth!

-Sizes:

R350, R400, R450, R550

-ESCO® Corporation also provides bolt-on shank shrouds

ESCO Toplok® Shrouds

ESCO Toplok® Shrouds

-ESCO® Corporation’s Toplok® is a fully mechanical shroud system that provides excellent bucket lip and wing protection for loaders and excavators.

-ESCO Corporation also provides bolt-on side cutters as well as weld-on lip and heel shrouds.

-Fastening consists of a pin, weld-on boss and shroud.

-Tooth Hardness (BHN):

-Toplok® Sizes:

Suitable for lip and wing thicknesses: 40mm to 160mm

-ESCO® Corporation also provides weld-on lip and heel shrouds

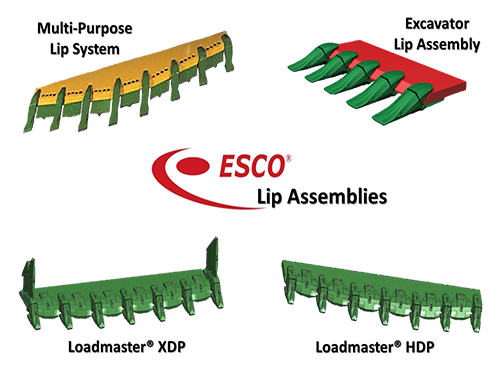

ESCO Bucket Lip Assemblies

ESCO Bucket Lip Assemblies

-The Loadmaster® HDP is constructed of a T1 plate and combines the ESCO Ultralok® tooth system with Toplok® lip and wing shrouds.

-The Loadmaster® XDP is constructed of a T1 plate and combines the ESCO Ultralok® tooth system with Toplok® lip shrouds.

-The Multi-Purpose Lip System is constructed of “Thru-Hardened” MaxTemp® steel and combines the ESCO Ultralok® tooth system with Toplok® lip shrouds.

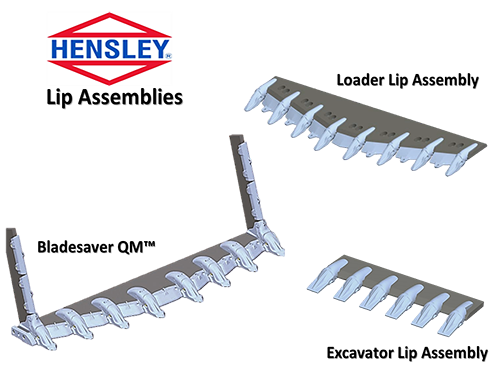

Hensley Bucket Lip Assemblies

Hensley Bucket Lip Assemblies

-The Bladesaver QM™ is a fully mechanical and hammerless loader lip system with streamline profiles for easier penetration as well as 100% lip protection The Bladesaver QM™ is constructed of a A514 plate and combines the Hensley XS® tooth system with hammerless lip and wing shrouds.

-Hensley Loader Lip Assembly is constructed of a A514 plate and combines the Hensley XS® tooth system with bolt-on lip shrouds.

-The Excavator Lip Assembly is constructed of A514 plate and combines the Hensley XS® tooth system .